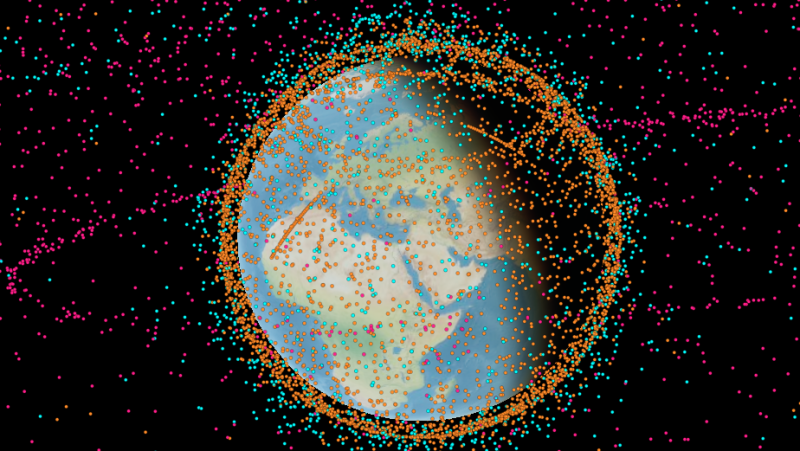

MoU of Space SMEs Aviosonic and HPS to join forces fighting space debris – right in time for Europe´s new constellation IRIS²

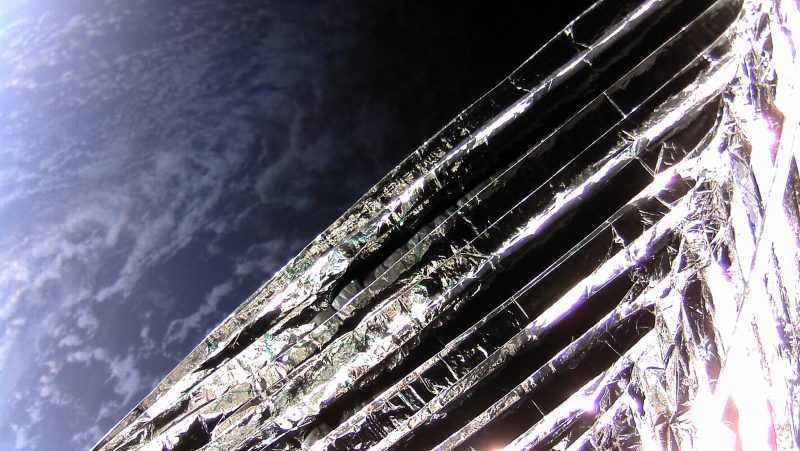

(Munich-Milano, May 11 th , 2023). At testified TRL-9 and with solid flight heritage the sail system “ADEO” already is the leading device for quickly deorbiting almost all satellites, thus preventing spacecrafts after their end of mission from becoming as well as producing new space junk for years to come. Because it is a sail, it does not produce any pollution itself, chemical or otherwise, and because this very sail will be in its next version also transparent and absolutely non-reflective, it does not cause any irritations to any space observer on earth. Munich based spacetech innovator HPS, a medium sized company with a subsidiary in Romania and a total headcount of 80, has invested – together with several institutional and industrial partners – 12 years of constant development and qualifying into ADEO, and is now ready to take yet another giant leap by joining innovative forces with Aviosonic Space Tech, Milan/Italy.

Aviosonic Space Tech, born in 2015, owns the patented DeCAS system (Debris Collision Alert System) for in-orbit/de-orbit tracking and re-entry footprint prediction of space vehicles. DeCAS is a 1U mm system which always maintains a constant link with the ground operation center allowing precise information on the satellite position, along with the calculation of the re-entry footprint in real time, with the aim of collision avoidance between satellites, satellites and aircrafts as well as to alert government agencies. The technical characteristics and modularity allow DeCAS to be installed on any space vehicle, offering different services depending on the mission requirements. DeCAS, which took part in different space missions, provides a unique service or satellite tracking, decommissioning and re-entry prediction in real-time.

Prof. Piermarco Martegani, CEO of Aviosonic Space Tech says:”The integration between DeCAS and ADEO allows the creation of a unique product on the market capable of strongly implementing the safety of space operations both during orbital and decommissioning re-entry phases, even in the event of failure of the hosting satellite. This safety information is also needed by the Air Traffic Management System. The collaboration between Aviosonic Space Tech and HPS is the demonstration that in order to guarantee safety during space operations, an international cooperation between SMEs is necessary.”

HPS-CEO Ernst K. Pfeiffer shows bulletproof confidence in the future of ADEO on the world market and emphasizes: “ADEO has all the facts on its side: first, all space industry badly needs a deorbit device like ADEO, since the faster the sail opens free orbit positions, the longer we can keep space as a sustainable surrounding. And, from second to infinite: ADEO combines TRL9 and flight heritage, offers a comprehensive range of models, beats economically as well as ecologically any other type of deorbit device, also it is already in serial production at HPS. And now we even join forces with the two outstanding innovators in their fields, and others will join, underlining once again what´s at the core of ADEO: 100 percent European, 100 percent SME, 100 percent sustainability in space – and exactly what Europe wants for IRIS².”

Point of contact

HPS: Daniel Stelzl, stelzl@hps-gmbh.com

Aviosonic: Prof. Piermarco Martegani, info@aviosonic.it

ADEO

German: https://www.hps-gmbh.com/tag/adeo/

English: https://www.hps-gmbh.com/en/tag/adeo-en/

Video: https://youtu.be/pUeSZzdn_6c