With the launch of the Heinrich Hertz satellite in 2023, Germany will once again be flying the black-red-golden flag in satellite telecommunications – twenty years after the DFS Kopernikus mission completed in 2002 – on the innovative “Small Geo” platform from OHB 36,000 kilometers above the earth. On board Heinrich Hertz are some 20 experiments on communications, antenna and satellite technology being conducted by institutes and companies to thoroughly test new satellite communications technologies for their suitability under the extreme conditions of space. Heinrich Hertz is nothing more and nothing less than the decisive step in the German space strategy to regain a foothold in the field of telecommunications with system capability of its own industry – on satellite and equipment level.

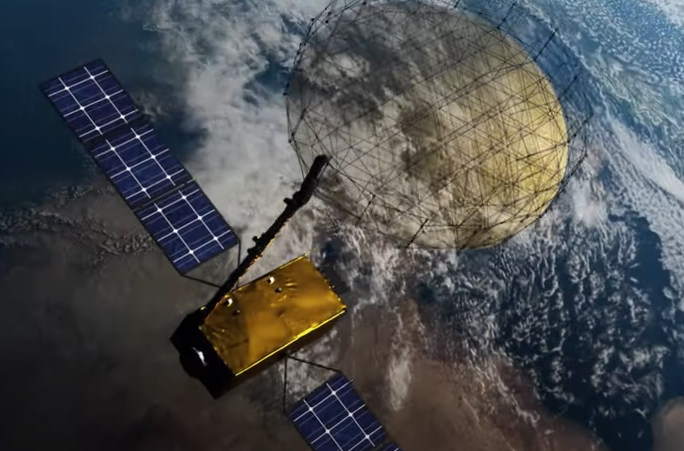

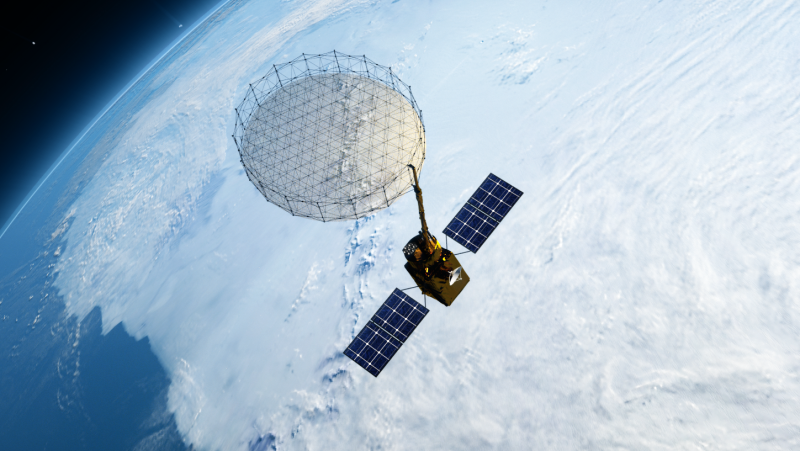

Beyond the previous design standard of installing only the receiving, forwarding and transmitting technology on a communications satellite, Heinrich Hertz has onboard processors for direct information processing and, in addition, for flexible readjustment of the satellite itself during operation. In addition to scientific mission objectives, the Ministry of Defense and the Ministry of Economics intend to use additional payload capacities for their own communications. And finally, Heinrich Hertz also serves as a relay station for smaller earth-orbiting satellites with a mass of up to 800 kilograms, extending their contact times to around 40 minutes each, thereby considerably increasing the amount of data transmitted.

All political and technical ambitions of the project depend crucially on the reliability of the invisible umbilical cord of data transmission between heaven and earth, satellite and ground station. With the successful test of the laterally deployable H2NBA antenna – the abbreviation stands for “Heinrich Hertz North Beam Antenna” – from the German antenna specialist HPS, this hurdle has now been overcome: The surface measurement of the reflector with laser radar tested 0.04 mm RMS (average deviation) over the entire reflective surface, the unfolding test in the HPS laboratory with 0-g compensation mechanics went off without a hitch; the antenna also passed vibration tests in all axes at the testing company IABG, Munich, under the extreme load of 25 times the acceleration due to gravity and acoustic tests up to 142.5 dB – this corresponds to the volume of a launching rocket.

The CFRP-based antenna including reflector, feed and tower, hold-down-and-release, deployment and pointing mechanisms from HPS or their subcontractors, is extremely lightweight yet dimensionally stable, offers high natural frequency and is suitable not only for the intended data transmission in the high-frequency Ka-band, but also for the even higher frequency band Q/V-band.

2020-H2NBA_Acoustictest -2

Following final on-time thermo-elastic and RF tests, the antenna will then be joined to the satellite in 2021/22 by the main contractor OHB.

HPS CEO Ernst K. Pfeiffer: “I am pleased and delighted with the results of the tests because even after a quarter of a century in space technology, as a passionate engineer you still break into a sweat during the murderous vibration tests at the latest. My respect to our structural engineers, who calculated all this so perfectly in advance and to all my test leaders who worked really persistent and carefully the last month to have a successful test! We are proud to be part of this groundbreaking mission at such a crucial point as specialists for both rigid and large deployable antennas, which we have been able to become thanks to the continuous support of DLR Space Agency and of ESA. After 20 years company history, with now 71 employees at our Munich locations and Bucharest, we stand for the M in SME at the level of the German as well as European space industry.”

HPS GmbH

Point of Contact: Dr. Ernst Pfeiffer, CEO

E-Mail: info@hps-gmbh.com

Telephone: +49 (89) 4520576-0